This year, the EMBA module in Russian, dedicated to "Operational Management", began with a visit to the Mercedes Benz Manufacturing Rus plant in the Moscow region. The study of the topic is always accompanied by a business visit to the enterprise, in the language of operational management, a visit to the gemba, a place of value creation.

The opening of the Mercedes Benz Manufacturing Rus plant two years ago was accompanied by a media company, the presence of Mercedes Benz management and the President of Russia. The factory still proudly keeps the hood, which was signed by President Putin and Dieter Zetsche, CEO of the company. At the moment, the plant already produces 4 models of cars and covers the needs of the Russian market by 85%. Localization of production increases every year.

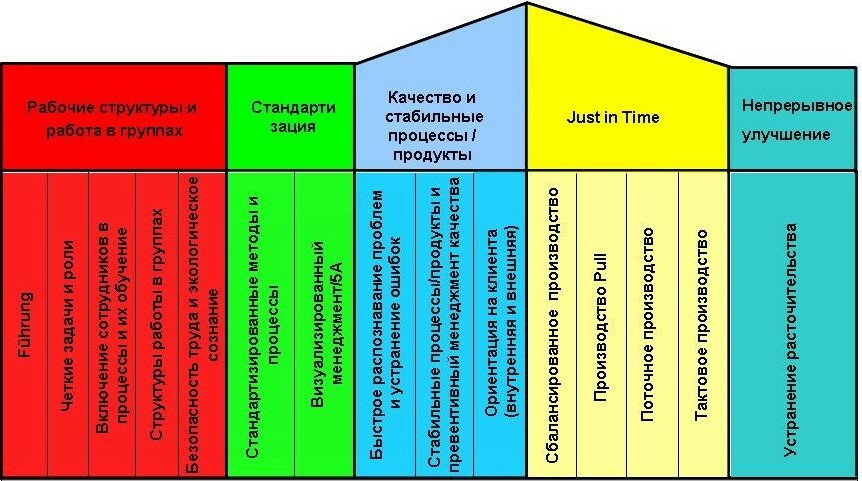

Pavel Bilenko, a teacher of the course "Operational Management", drew attention to a special element that is part of the Mercedes Benz Production System. This element was left without translation on the Russian-language scheme of the Mercedes Benz PS.

The fact is that "Fuhrung" has several meanings: "leadership", "vision", "direction", "visit" – that is, this capacious word reflects its own, German version of a visit to gemba.

The Faculty of International Programs of the Kingston MBA/RANEPA and the EMBA program in Russian is grateful to the management of Mercedes Benz in Russia and Germany for the opportunity to study in practice the unique production experience of the company. We also express our special gratitude to our permanent partners in organizing field events – the Russian-German Chamber of Commerce in the person of Vladimir Nikitenko and Svetlana Bechtold – for the brilliant organization of the visit.

Speaking of operational management, of course, we could not ignore the classics – the TOYOTA Production System. Many companies, when creating their own production systems, take TPS as a basis to one degree or another. So did the companies "KAMAZ", "Technonicol", the Kalashnikov Concern, Sberbank. Herman Gref once noted: "Perhaps the best thing that TOYOTA has given the world is not cars, but the TOYOTA Production System."

Pavel Mikhin is the presenter of the TOYOTA Production System on the EMBA program in Russian. Pavel has worked at the TOYOTA Boshoku plant in the Leningrad Region for more than 6 years, almost from the day of launch, and knows in detail how this unique company functions from the inside. Practical expert sessions with Pavel are always highly appreciated by the listeners of the program.

At the dawn of the transformation, Sberbank's Board meetings used to begin with the question: "Who knows what TPS is?". Not all Board members could answer this question. Since then, a lot of time has passed, Sberbank has changed beyond recognition, has become a symbol that "an elephant can be taught to dance." And now the most flexible (agile) bank in the country demonstrates that service organizations can have successful production systems.

The conversation about operational management in service organizations is continued by Vasily Shelkovoy, head of the Beber Production System. The most profitable bank in Europe for 2020, the 10th place in the world ranking - part of this success of Sberbank lies, among other things, in the ability to establish effective operational processes, minimize losses.

The study of successful, proven practices helps students of the program to improve operational processes in their companies, adapt the acquired knowledge to their business, context, use knowledge plastically, first for critical rethinking, search for points of improvement, and then to create new technologies, techniques and their own authentic production systems.

We live in a very dynamic time. Pavel Bilenko emphasized that even such symbols of operational efficiency as TOYOTA and TPS have to adapt to the onslaught of digitalization, the transition to Industry 4.0. This evolutionary improvement of processes is the essence of operational management.

Vasily Zorin, 1st year student, EMBA program in Russian

"The third module of the EMBA program has come to an end. I felt in my gut the synergetic effect that space teachers, speakers and no less space classmates give. With difficulty and honestly delved into corporate finance, feeling the interrelationships with his fingertips when calculating the value of the company through the compound interest formula.

I listened to a song about lean manufacturing, production systems of companies, I knew a lot about it, applied it, tried to teach it, and, nevertheless, I rethought a lot using the examples of the TOYOTA Production System and the Sberbank production system. A pleasant bonus was not only to hear, but also to see the production processes of Mercedes Benz at the factory."